Extraordinarily skinny ceramic coatings can fully change the properties of technical elements. Coatings are used, for instance, to extend the resistance of metals to warmth or corrosion. Coating processes play a task for big turbine blades in addition to for very pressured instruments in manufacturing expertise.

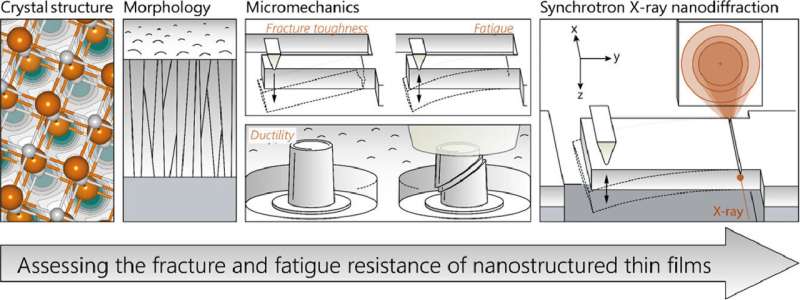

TU Wien (Vienna) has now investigated what determines the soundness of such coatings. And the outcomes, a few of which had been obtained on the DESY synchrotron in Hamburg, are fairly shocking: the ceramic layers break down in a very completely different manner than metals. Materials fatigue hardly performs a task; the decisive issue is the depth of utmost load peaks (the so referred to as stress depth issue). This discovering will change the tactic used to measure and additional enhance the resistance of skinny movies sooner or later.

The examine is revealed in Acta Materialia.

Confused thousands and thousands of occasions

“In lots of functions, periodic hundreds are a giant drawback,” says Prof. Helmut Riedl, head of the Utilized Floor and Coating Expertise analysis group on the Institute of Supplies Science and Expertise at TU Wien. “Should you expose steel elements to a sure drive again and again, adjustments happen on a microscopic scale.” Some atoms could shift, layers are fashioned that may slide previous one another, tiny cracks can develop and finally result in the fracture of your entire part. Such material fatigue results are ubiquitous in engineering, and they’re well-studied.

What occurs to skinny coatings underneath stress, nonetheless, is much less clear. “Ceramic coatings are sometimes only some nanometers to 10 µm thick, their habits is totally completely different from that of a stable piece of ceramic,” says Lukas Zauner, who’s engaged on his dissertation within the Utilized Floor and Coating Expertise Analysis Group.

To achieve the deepest understanding of this habits, fully new measuring strategies had been developed at TU Wien: As an alternative of testing steel and ceramic coating collectively, as is often performed, the workforce neglected the steel, produced extraordinarily skinny samples of assorted ceramic supplies usually utilized in thin-film expertise and uncovered them to numerous hundreds in a exactly outlined manner—again and again, as much as ten million occasions.

X-rays on the synchrotron

So as to discover out precisely whether or not the atomic construction of the ceramic adjustments because of this, the workforce took the experimental set-up to Hamburg: there, extraordinarily well-focused X-rays can be found at DESY’s synchrotron, which can be utilized to look at numerous factors of the pattern in the course of the loading experiment. Even tiny adjustments within the crystal structure or within the distance between neighboring atoms needs to be detectable on this manner.

However surprisingly, these measurements confirmed: The ceramic virtually doesn’t change. Even thousands and thousands of load cycles don’t result in materials fatigue. “Customary ceramics would fatigue in line with sure patterns, just like the form of fatigue we all know from metals. However these extraordinarily skinny layers don’t present this habits,” says Helmut Riedl. “Their microstructure is similar on the finish because it was in the beginning.”

Which means that the sturdiness of the skinny layers is set solely by their fracture toughness: Should you exceed a load restrict attribute of the fabric, then the layer is destroyed—all of a sudden and irreversibly. Nevertheless, all hundreds beneath this restrict will not be an issue, they don’t age the ceramic layer, they’ve virtually no impact.

New analysis methods

“In fact, this additionally adjustments the technique how analysis initiatives for brand spanking new, improved ceramic coating supplies are designed,” says Helmut Riedl. “You do not have to do prolonged long-term assessments, it is sufficient to search out out by a easy load take a look at which materials breaks underneath which drive. You do not have to fret about the right way to probably alleviate fatigue results within the materials, you simply have to search out supplies with the best potential fracture toughness—even this isn’t a easy job by itself.”

The workforce has already been capable of finding a wonderful candidate for this: a sure type of chromium diboride proved to be surprisingly resistant within the assessments. This paves the way in which for future, promising analysis gaining best success.

Extra data:

L. Zauner et al, Assessing the fracture and fatigue resistance of nanostructured skinny movies, Acta Materialia (2022). DOI: 10.1016/j.actamat.2022.118260

Offered by

Vienna University of Technology

Quotation:

Nanostructured ceramic coatings don’t fatigue, finds examine (2022, November 17)

retrieved 17 November 2022

from https://phys.org/information/2022-11-nanostructured-ceramic-coatings-fatigue.html

This doc is topic to copyright. Aside from any honest dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for data functions solely.